Electronic Repair Services

At Encore Repair, we provide cutting-edge repair and refurbishment of electronic devices and innovative business models. We help our customers achieve a higher return on investment by maximizing the devices’ residual value through the industry’s highest-quality production processes, state-of-the-art remanufacturing capabilities, and extensive research and development facilities which optimize cost/benefit.

Cosmetic Repair

Cosmetic repair and enhancement services are critical to capture the residual value of electronic devices for a secondary market.

Encore’s proprietary cosmetic repair processes are focused on capturing the residual value of electronic devices for a secondary market at the right cost

Cosmetic repair and enhancement services are critical to capture the residual value of electronic devices for a secondary market.

Encore’s proprietary cosmetic repair processes are focused on capturing the residual value of electronic devices for a secondary market at the right cost

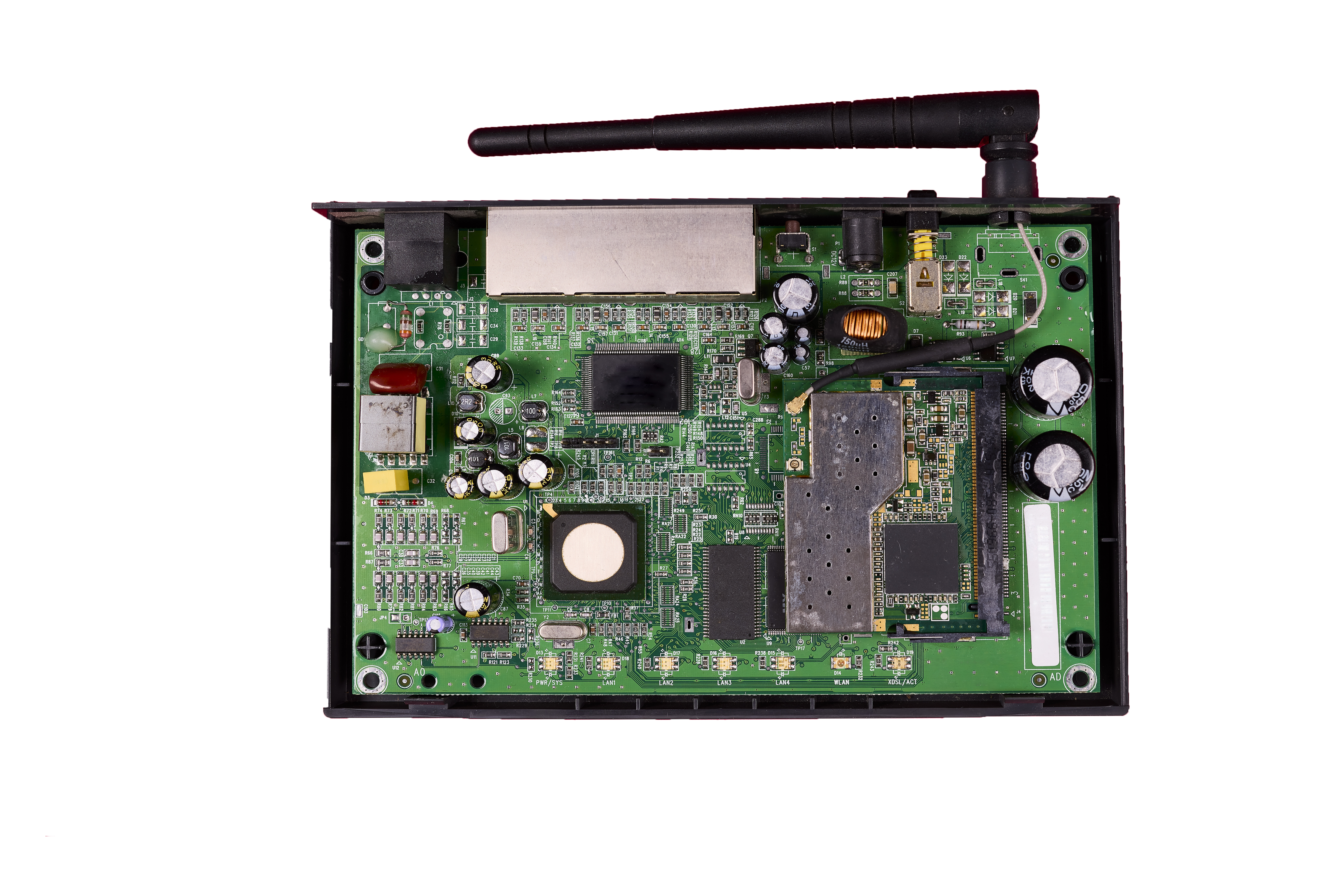

Device Repair

An electronic device’s life-cycle depends on market reintroduction in “customer-ready” condition.

Our established team of technicians utilizes state-of-the-art tools and equipment to provide solutions to maximize a device’s life-cycle.

In & Out of Warranty Repair

As a trusted service provider, Encore has OEM relationships that enable us to obtain original parts, components, and access to BOMs, maximizing efficiency and ensuring the highest quality repair services.

As a trusted service provider, Encore has OEM relationships that enable us to obtain original parts, components, and access to BOMs, maximizing efficiency and ensuring the highest quality repair services.

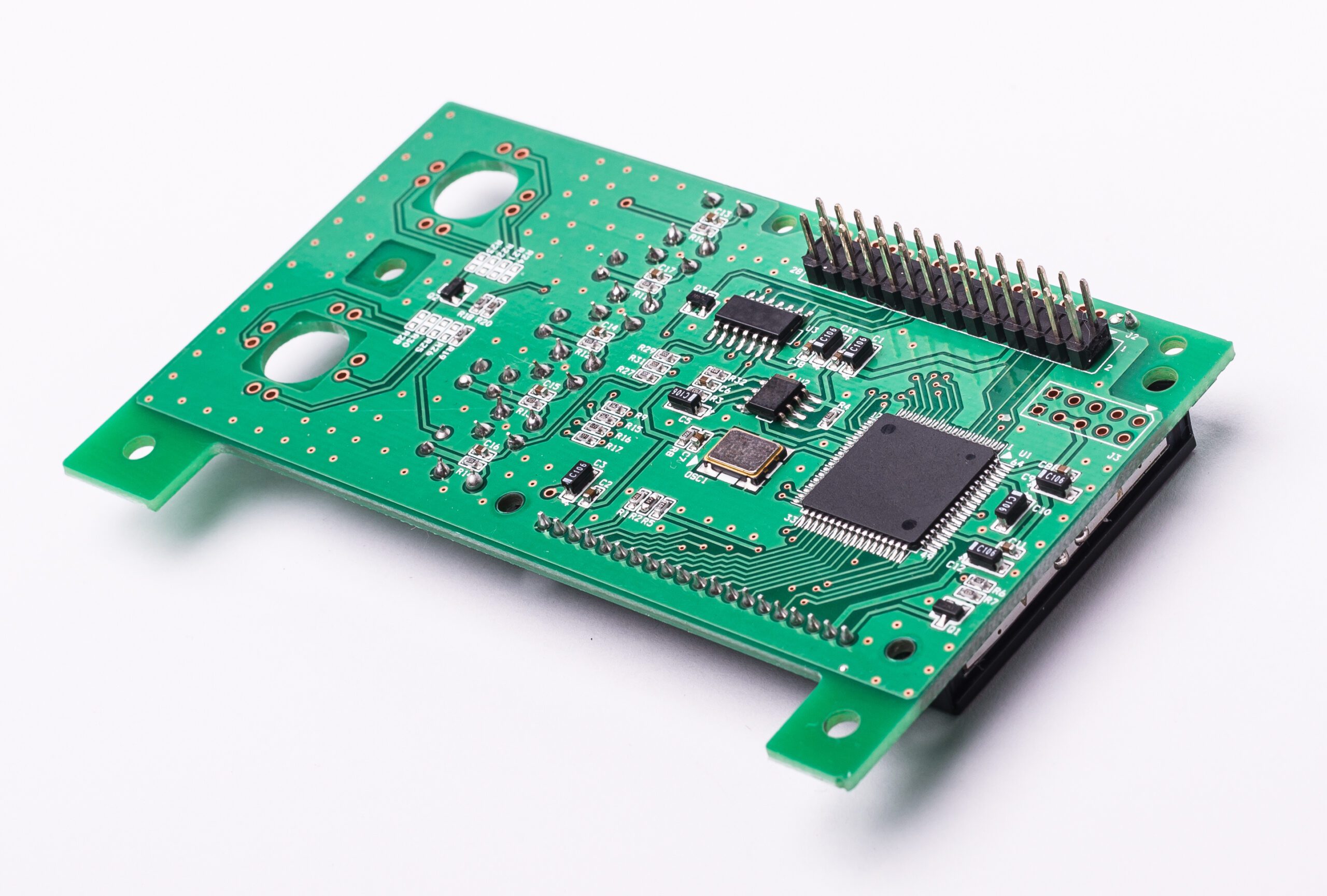

Board Level Repair

Capture Residual Value

Device Grade Enhancement

Encore’s proprietary cosmetic repair processes are focused on capturing the residual value of electronic devices for a secondary market at the right cost

Image shown for representational purposes only

A Simple Component Repair Drives Monetization

Our engineering team continuously trains to learn the newest technological advancements and implement processes and procedures to access faulty components, in turn restoring a device for the secondary market.

We are committed to sustainability: Major component reclamation capabilities and a highly skilled workforce allow for rapid processing and quick turnaround times.

Connect With The Encore Team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.